Our Process

In Partnership With

McArthur BDC works with several manufacturers to ensure we have a comprehensive range of options available to our customers. Two prominent manufacturers are Westfield and SØBY. Canadian manufacturer, Westfield, has the worlds largest specialised grain auger factory. Typically producing mobile, high capacity, outdoor augers for filling silos. Danish manufacturer, SØBY, was established in 1961 and manufacturers a wide range of premium grain handling and storage products including auger conveyors, trough augers and sweep augers.

The Westfield range of augers is comprehensive. The MKX is the flagship range of tractor driven mobile augers with diameters ranging from 203mm (8”) to 406mm (16”) delivering capacities ranging from 110 tonnes per hour to 550 tonnes per hour. The largest auger in the range has a length of 37.5m. The smaller WX series can be either tractor driven or powered by three phase electric. Auger diameters range from 203mm (8”) to 330mm (13”) and capacity from 45 tonnes per hour to 104 tonnes per hour at a 40 degree incline. Both ranges feature a range of inlet and outlet hopper options to suit each specific application.

SØBY manufacture several ranges of auger including the trough auger, conveyor auger and sweep auger. The trough auger range has capacity ranging from 20 tonnes per hour to 60 tonnes per hour. The tubes, inlet hopper and outlet hopper, are hot dip galvanised to deliver maximum durability and augers are specified with gearmotor drives. The length of the trough auger ranges from 0.5m to 22m.The conveyor auger range is renowned for its uncompromising build quality, with heavy duty tubes, flights and transitions. All augers are hot-dip galvanised with double bearings on top shafts. The range has auger diameters from 102mm (4”) to 254mm (10”) and length is made up of extension sections between 1m to 6m, connected with sleeve joints.

Key Features

- Simple to setup and use

- Broad range of dimensions and capacities available

- Able to move grains, pellets, meals and other granular materials

- Galvanised construction as an option

- Comprehensive range of inlet and outlets

- Capacity, length and build to suit each situation

- Simple assembly process on site

Why Augers

Augers are a cost effective method to handling grain, simple and effective they are a common site across all farms

Why Westfield & SØBY

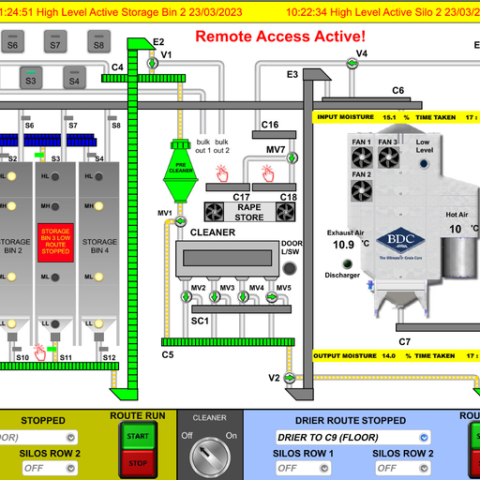

Both Westfield and SØBY manufacture high quality products. The Westfield equipment is well suited to silo filling applications whereas the SØBY equipment is perfect for incorporation into a grain drying or processing systems that are in regular use.