Our Process

In Partnership With

Founded in 1935 Akron has manufactured a wide range of products for both the agricultural and other engineering sectors from its base in Järpås, Sweden. The business combines substantial technical and design capability with a state-of-the-art production facility for grain drying and storage equipment. Akron produces equipment components for stock so can deliver new machinery in full on very short leadtimes.

The Svegma drier is manufactured from heavy gauge galvanised steel sheet. The compact and modular design ensures quick installation even in confined spaces. There are a large range of models available in five widths 2m – 8m and capacities from 8 tonnes per hour to over 100 tonnes per hour. The unique lateral fixing system means there are no fixings, flanges or ledges in the grain column, ensuring continuous unobstructed movement of grain in the trickiest conditions.

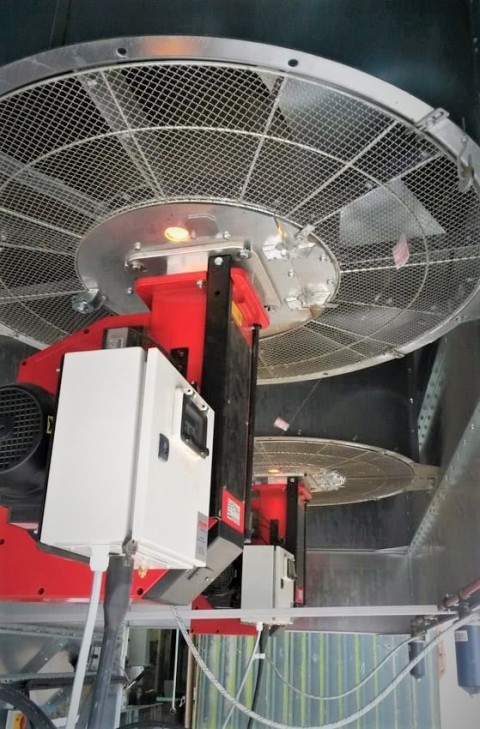

The Akron axial fans used on Svegma grain driers are developed specifically for the application, highly efficient and slow running they ensure drier performance while minimising noise levels. Fans can be mounted on the front, side and roof of the drier and a range of attenuators, shutters and additional ducting is available. Akron have also developed the highly effective Turboclean dust extraction fan, designed to separate dust from the exhaust air, independent testing recorded a 95% reduction in visible dust particles.

The Svegma drier can be used in conjunction with a range of heat sources including, oil burners, both direct and indirect. Gas burners either LPG or mains natural gas and various biomass systems. The control panels are manufactured for each unique grain drying system including the grain drier. The latest control panels include optional features such as a large touchscreen, remote monitoring and automatic grain drier controls based on grain moisture. The moisture monitoring system continuously measures the moisture of grain and can adjust the driers speed automatically to prevent over-drying and reduce energy costs.

Key Features

- Manufactured in heavy gauge galvanised sheet

- Highly flexible and modular design

- Capacity from 8tph to over 100tph

- Mixed flow design optimises efficiency

- Fuel options include oil, gas and biomass

- Akron fans design for specifically for Svegma driers

- Intuitive control panel design

- Moisture monitoring system and other innovative features

Why Continuous Flow Grain Driers

The capacity of continuous flow grain driers allows them to dry and cool grain ready for storage as quickly as it comes off the combine. This combination of productivity and speed is unmatched by any other grain drying system.

Why Svegma

The Svegma continuous flow grain drier, manufactured by Akron, has long proven its capability on the UK and Irish market. Fans manufactured specifically for the Svegma drier ensure outstanding performance while minimising energy costs.