Our Process

The control panels are available in two options, digital and PLC. The digital version uses older technology to deliver the key functionality required in any system. The PLC option is more feature rich and offers great functionality and essential on larger, more complex plants.

Digital Control Panel

The digital panel is a hard wired system with relay logic control. The simple design and ease of fault finding make this a simple panel to operate and maintain. Features include, digital fail-safe auto shutdown and temperature controls for the drying process. The panel has automatic discharge control and regulates grain moisture content based on exhaust air temperature. The engraved mimic with digital displays and indicator lights provides a clear overview of the plants operating status.

PLC Control Panel

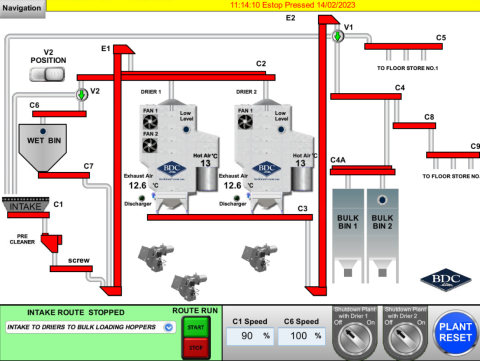

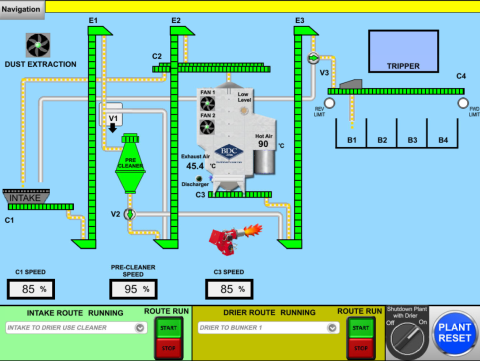

The PLC control panel features a well-sized touchscreen display. The display has an intuitive layout and displays the plant status and all key information including hot air temperature, exhaust air temperature and discharge rate. The panel has automatic discharge control and regulates grain moisture content based on exhaust air temperature. The PLC control panels monitor alarm conditions including low level, hopper full and hot air or exhaust air overheat and notify operators of issues. A complete history of the plants operation which can be downloaded to a USB stick. During operation information can also be inputted manually, which crop is being dried and moisture content of the crop, this aids traceability and record keeping.

The McArthur BDC developed Moisture Monitoring System is fully compatible with all PLC control panels on Svegma grain drying plants and may be retrofitted, improving the accuracy and control of the grain drying process.

All new PLC control panels can be remotely accessed to monitor and manage the plants operation from a PC, tablet or smartphone. Remote access also allows product support technicians to access the PLC remotely to support fault finding or make modifications to the control panels function as required.

Key Features

- Wide range of functionality

- Intuitive, easy to use design

- Extensive plant safety features

- Remote access and control options available

- Download and store information

- Customised design for each system

Digital or PLC Control Panel

Both the digital and PLC control panel provide the functionality required for a grain drying, storage and processing plant. The digital panel is a simple, easy to maintain system. For larger more complex plants where operators require remote access the PLC control panel is more suitable. This PLC system also better lends itself to future expansion of the plant.

Why McArthur BDC?

Years of hands on technical and practical experience are captured in the latest BDC System's control panels. The control panel is the brains of the grain drying, storage and processing plant and as important as the initial design and build of the control panel. BDC System's provide continuous support during the design stage, build and aftercare stage.