Our Process

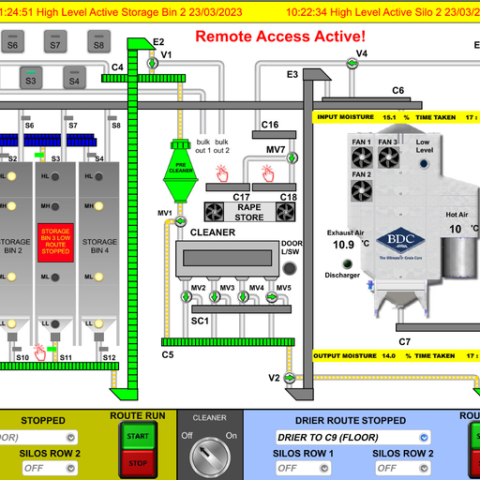

The Moisture Monitoring System provides automated, accurate grain moisture data to your grain drying system. The system comprises of several key components

- A sampler for wet grain, before the drier

- A sampler for dry grain, after the drier

- The moisture measurement module

- The control system, either standalone or incorporated into the plants control panel

Design features include automatic moisture sampling and live moisture percentage of both incoming wet grain and outgoing dry grain, all recordings are logged allowing traceability of the crop. The onscreen graph shows a moisture trend within the crop and subsequently triggers a warning for crops below or over moisture percentage. The ability for remote viewing is a favoured design feature to support crop recordings.

The savings delivered by accurate grain drier control are significant, consider the following example which shows the cost of over drying wheat from 19% to 13%, as opposed to 14% moisture content.

- Additional water loss of 10.83 tonnes leads to a loss of £1,895 (based on wheat at £175/tonne)

- Additional fuel use of approximately £1,240 litres at a cost of £930 (based on heating oil at £0.75/litre)

- Additional electric use of 200kWh at a cost of £100 (based on electric at £0.5/kWh)

- 16% - 20% reduction in drier throughput due to longer required drying time

The additional cost of 1% over drying on 1,000 tonnes of wheat based on the assumptions provided is £2,925, almost £3/tonne. The investment in the MMS technology depends on tonnage dried each year however, delivering these kind of saving ensures a breakeven and good retrun on investment without considering the implcations of reduced labour due to automation of the drier control.

Key Features

- Automatic moisture sampling and live moisture percentage readings

- All recordings are logged supports crop traceability

- Trigger warning for crops below and above recommended moisture

- Ability to remotely view recorded results

- Supports crop preservation

- Accurate monitoring helps efficiency providing financial savings

Why Moisture Monitoring System

The Moisture Monitoring System provides accurate and automated grain moisture data. Preventing the over drying of crops reduces weight loss and the incursion of unnecessary operating costs. The recording of data provides traceability of crops with the live graph showing the moisture trend within the crops.

Why Sinar Technology

The Moisture Monitoring System has been developed to ensure accurate, repeatable and dependable measurement of grain moisture. It is a result of significant research and development by the technical team that is proven on commercial systems across the UK.